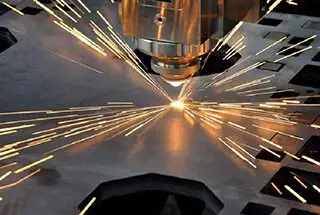

In today's world, technology has made it possible to cut metal with precision and accuracy that was unimaginable decades ago. One such technology is laser metal cutting which has completely revolutionized the metal cutting industry. Laser metal cutting service provides a wide range of benefits, from precision cutting to high-quality finishes. In this blog post, we will explore the benefits of laser metal cutting service and its impact on the metal cutting industry.

Laser metal cutting service is a process that uses laser technology to cut sheets, tubes, and pipes made of different types of metals such as aluminum, steel, and titanium. Unlike traditional cutting methods, where a blade is used to cut through metal, laser metal cutting is a non-contact process that uses a high-powered beam of light to vaporize the metal in a precise and controlled manner. The laser metal cutting process is highly automated, and it offers greater speed and efficiency compared to traditional cutting methods. The result is a high-quality finish that is free of burrs, rough edges, and distortion.

One of the biggest advantages of laser metal cutting service is its accuracy, which is second to none. Laser metal cutting machines can cut through metal with a precision of up to 0.1 mm, making it ideal for applications that require high precision and accuracy, such as aerospace, automotive manufacturing, and medical devices. As the demand for precision metal cutting increases, laser metal cutting is becoming the go-to technology.

Another significant benefit of laser metal cutting service is its versatility. Laser metal cutting machines can cut through a wide range of metals, including brass, copper, stainless steel, and even precious metals such as gold and silver. This versatility is essential for applications that require different types of metals to be cut in a single process, which is not possible with traditional cutting methods.

Laser metal cutting service is also a cost-effective solution. While the initial investment for a laser metal cutting machine may be higher compared to traditional cutting methods, the cost per part is significantly lower due to the high speed and efficiency of the process. Additionally, laser metal cutting machines have a longer lifespan than traditional cutting machines, which translates to lower maintenance costs and higher productivity.

Another significant advantage of laser metal cutting service is its speed. Laser metal cutting machines can cut through metal at a speed of up to 100 meters per minute, depending on the type of metal being cut and the thickness of the material. This speed is significantly higher compared to traditional cutting methods, which translates to faster turnaround times and increased productivity.

In addition to its speed, accuracy, and versatility, laser metal cutting service is also environmentally friendly. Unlike traditional cutting methods, laser metal cutting does not produce any harmful emissions or waste, making it a sustainable and eco-friendly option for metal cutting.

In conclusion, laser metal cutting service has completely revolutionized the metal cutting industry. Its accuracy, versatility, speed, and cost-effectiveness have made it the go-to technology for precision cutting of different types of metals. As technology continues to evolve, laser metal cutting will remain at the forefront of metal cutting, delivering high-quality finishes with unparalleled precision and accuracy. If you're looking for a reliable and efficient metal cutting solution, laser metal cutting service is the way to go.